The Importance of the Wear Layer Thickness in Wood Flooring.

Harlech Raw Oak

As a designer, you know that the flooring you choose can make or break the aesthetic appeal of a space. While it may seem like simply a design decision, the quality and longevity of the flooring you choose can impact your project’s budget and even your client relationships. It is function over fashion first. That’s why it’s essential to understand the importance of the wear layer thickness in wood flooring.

What is a wear layer?

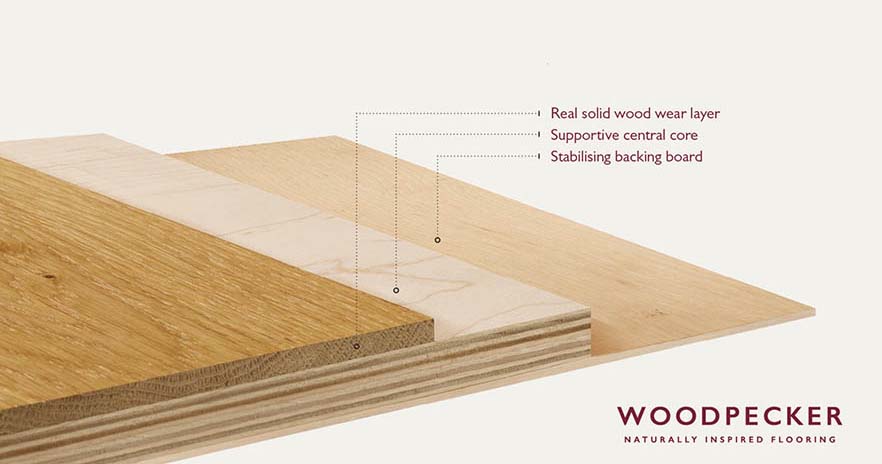

When looking at an engineered hardwood floor, the wear layer is the top layer of wood, which is designed to withstand foot traffic, provide dimensional stability and withstand everyday wear and tear. It is essential to consider the wear layer thickness when choosing wood flooring because it can determine things like how many times you can refinish the floor in the future.

What are the differences between wear layer options?

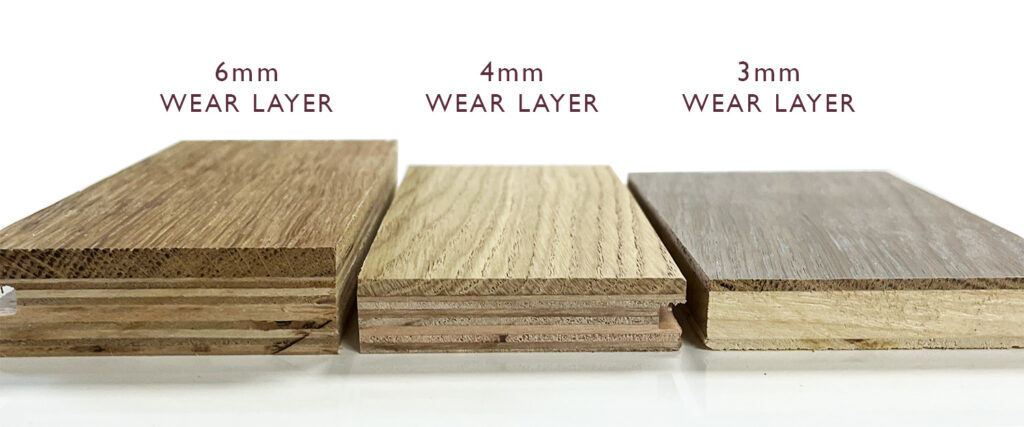

Wear layers come in different thicknesses ranging from .5mm to 6mm. A tongue and groove plank of engineered hardwood has about 6mm of wood from the top of the plank to the first tongue or groove, which means this is how much hardwood there is to refinish if needed. On average each refinish takes away 2mm of wear layer. The thicker the wear layer, the more times it can be sanded down and refinished. Therefore, if you’re planning to install a wood floor in a high-use area that may need to be refinished, it’s essential to choose a durable wear layer like 6mm.

However, if you are installing your engineered wood flooring over radiant heat, it is recommended to go with a moderate size wear layer, closer to 3mm (Salcombe collection) 4mm (Harlech and Berkeley collections) to reduce the risk of splits or cracks developing over time, increasing the wood floor longevity.

The type of wood used in the wear layer also impacts the durability and longevity of a wood floor. Hardwood, like European White oak is naturally more durable because of the region it is grown in, so it’s a popular choice because it has a natural resilience to wear and tear. Additionally, choosing engineered hardwood flooring with a thick wear layer gives you the durability of hardwood with added stability, making it a better choice for areas with fluctuating temperatures or humidity levels.

When considering the wear layer thickness, you also need to consider the level of foot traffic the area will receive. In a high-traffic area, it’s crucial to choose a thick wear layer that can handle heavy wear without looking worn or tired. In contrast, a low-traffic area may be suitable for a thinner wear layer, as it won’t receive as much wear and tear or need as much maintenance in the future.

A durable top layer can also minimize maintenance needs. Daily foot traffic and outside debris can damage the flooring’s appearance or even its stability in the long run. A thick and high-density top layer provides greater protection and increases a floor’s lifespan.

The wear layer is a crucial factor to consider for the longevity and maintenance of a wood floor. Careful consideration of the thickness, wood type, and expected foot traffic are crucial to selecting a wood floor with the appropriate wear layer level for your next project. With this understanding, you can choose wood flooring that meets both your design vision and practical needs, giving your clients a lasting impression of the beauty and functionality of their new space. If you want more information contact us